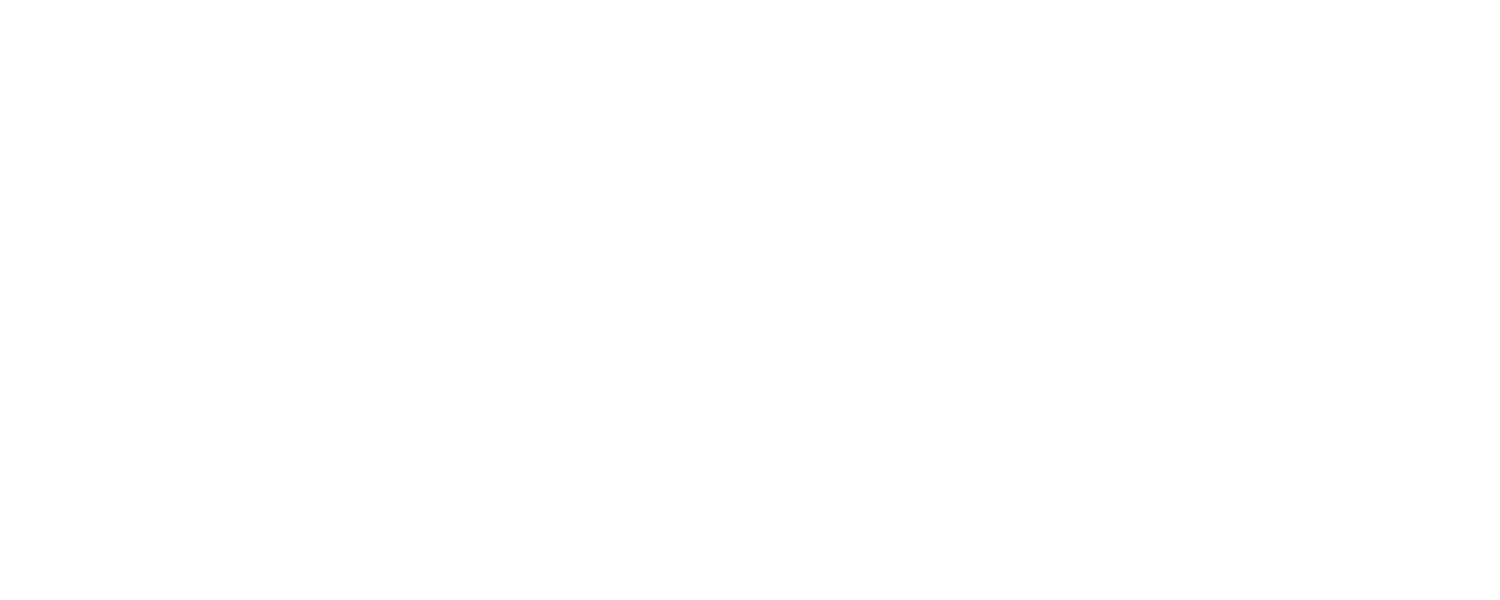

Laminated Copper and Aluminum Connectors

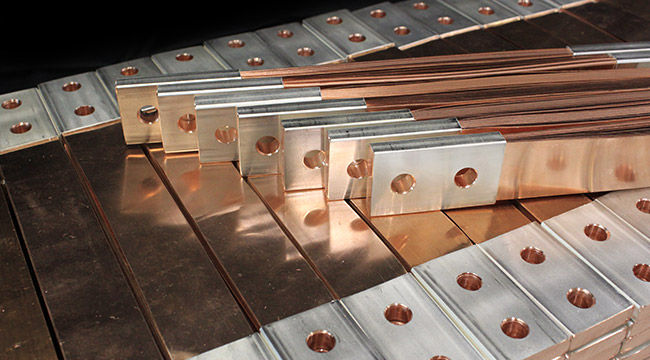

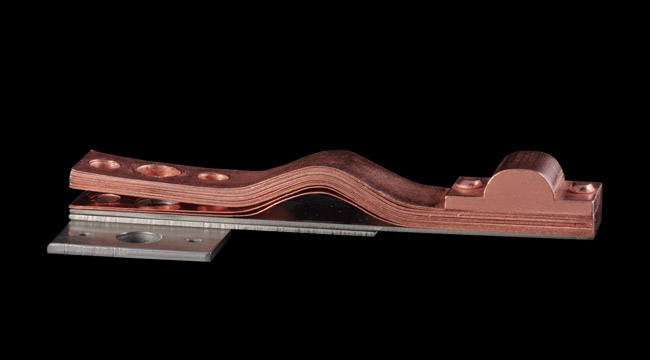

When flexible braided connectors are not an appropriate solution, laminated copper and aluminum connectors may be the perfect option. They maintain optimal levels of electrical and mechanical properties while sustaining the stresses of movement and heat.

As a result, laminated connectors protect your equipment and increase its operational lifespan. Using proprietary high-precision equipment, Exel manufactures laminated connectors to your specifications, and rigorously controls production quality.

Applications

Frequently used to fasten an electrical connection in extreme conditions, laminated connectors are mainly found under the following circumstances:

Low-vibration mechanisms

Minor thermal contractions and/or extensions of attached units

Low-level movement

Constrained spaces

Materials used

Strips

Tin-plated C11000 ETP copper as per ASTM B33

Silver-plated C11000 ETP copper as per ASTM B298

Nickel-plated C11000 ETP copper according to ASTM B355

Bare C11000 ETP copper as per ASTM B152

Aluminum alloy 1350 as per ASTM B209

Standard laminates vary in thickness from 0.005” to 0.04” and in width from 0.5’’ to 10’’.

Plating options

Electrolytic tin plating as per ASTM B545

Electrolytic silver plating as per ASTM B700

Electroless nickel plating as per ASTM B733

Lead-free hot tin dip plating

The standard thickness plating on a contact pad is 0.0003” although it can reach up to 0.004”, upon customer request.

overall DIMENSIONS

Width of connecting pad up to 24"

Thickness of connecting pad up to 1.5"

Total connector length unlimited

Mounting holes as per NEMA standards or custom

CURRENT CAPACITY

100 to 7,500 amperes, according to design specifications.