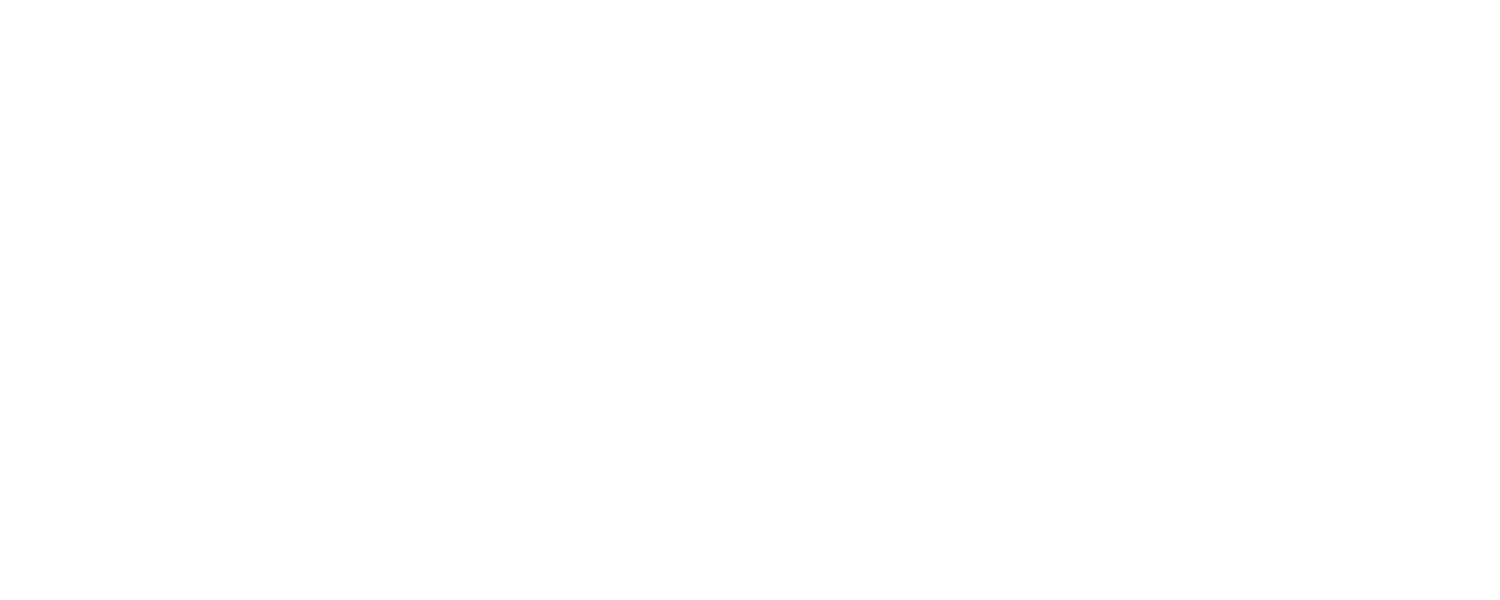

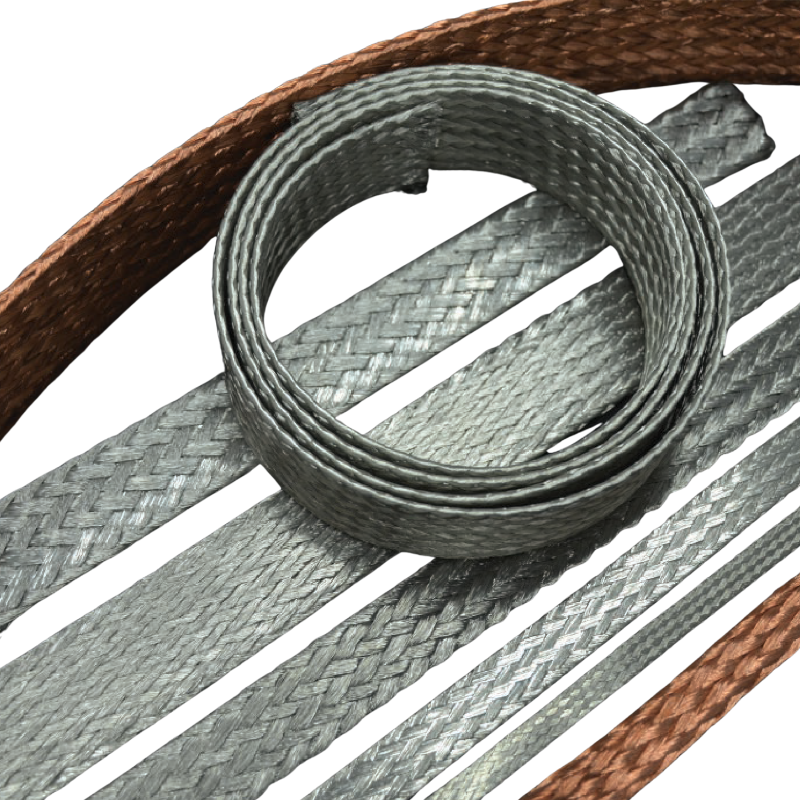

Copper Braided Cable

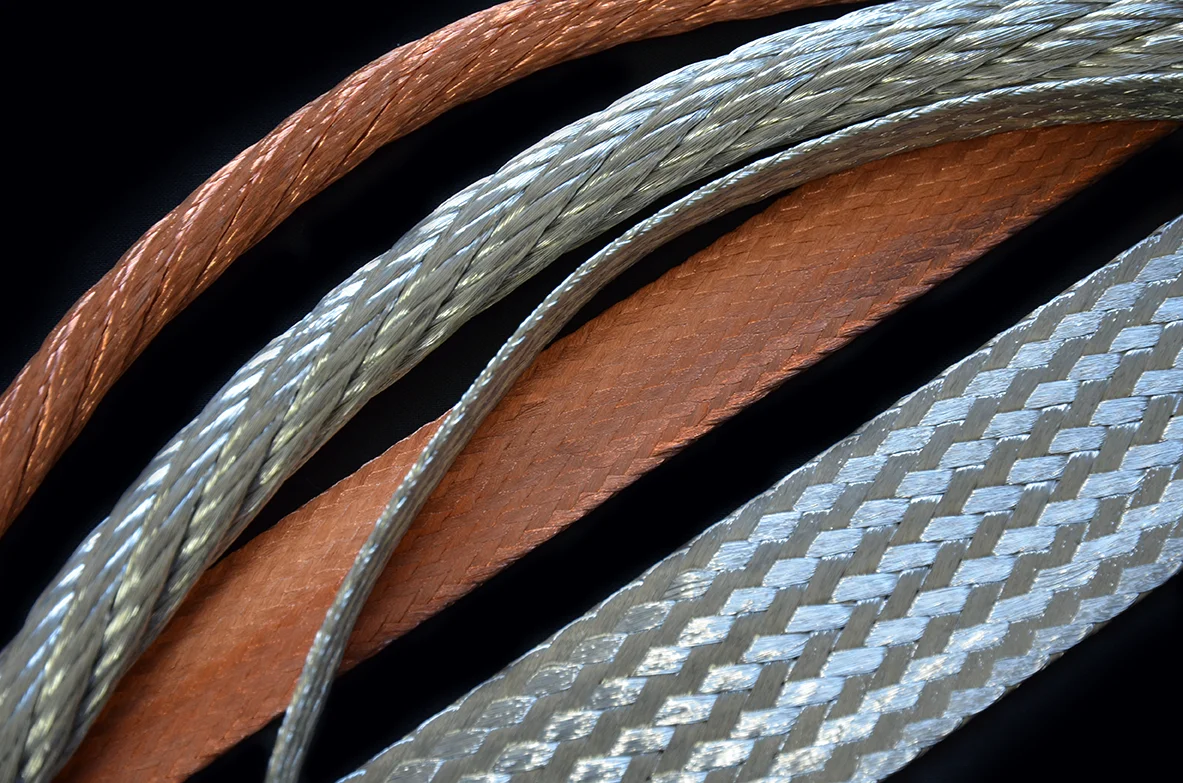

As the first Canadian manufacturer of copper braided cables, Exel International offers a wide range of high-quality flat braid products, including bare copper and tin-coated options. Manufactured in accordance with ASTM B3 and B33 standards, our copper braids are designed to meet the highest industry requirements. Primarily used for grounding applications in industrial environments, they can also serve as conductors in electrical systems. As a manufacturer, we provide custom solutions tailored to our customers’ specific needs.

Applications

Copper braided cables are essential in applications where electrical connections are exposed to significant movement or vibrations. Their flexibility and durability make them ideal for:

Absorbing mechanical stress in dynamic electrical connections

Enhancing electrical conductivity in grounding systems

Facilitating reliable connections in high-vibration environments

These characteristics make them widely used across multiple industries, including energy, automotive, aerospace, telecommunications, and military applications.

Technical Characteristics

Wires

Copper classification: as per ASTM B3

Designation: Cu-ETP

Minimum copper content: 99.9%

Surface Treatment of Wires

Electrolytic tin-plating: Nominal thickness of 0.1 μm (Class C) per ASTM B33

At Exel International, we are committed to delivering high-performance copper braided cables that meet the rigorous demands of modern industry. Contact us today to discuss your specific requirements and discover how our expertise can provide the perfect solution for your application.

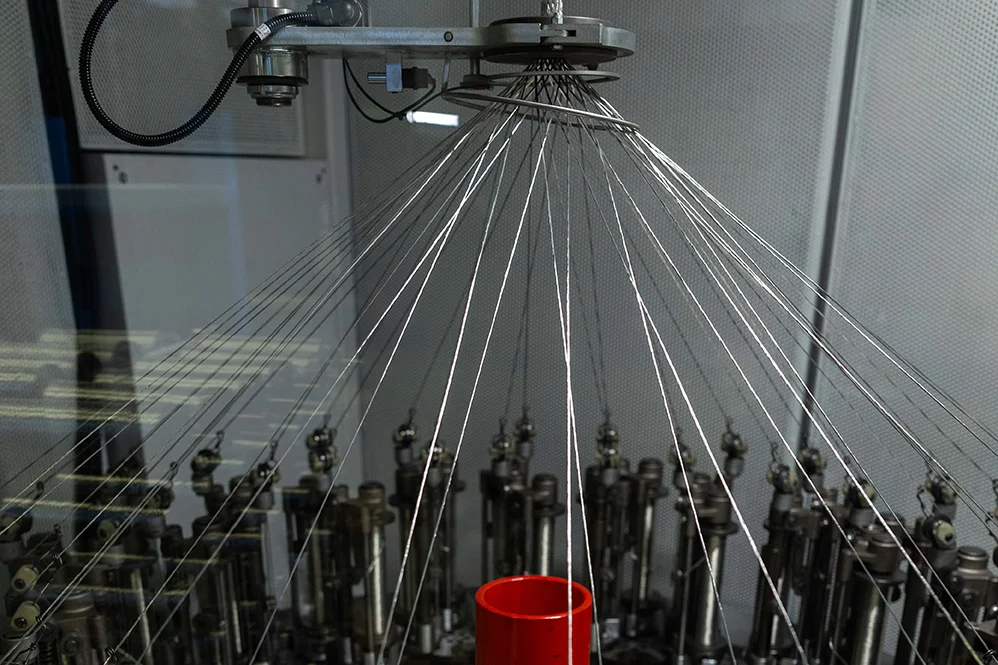

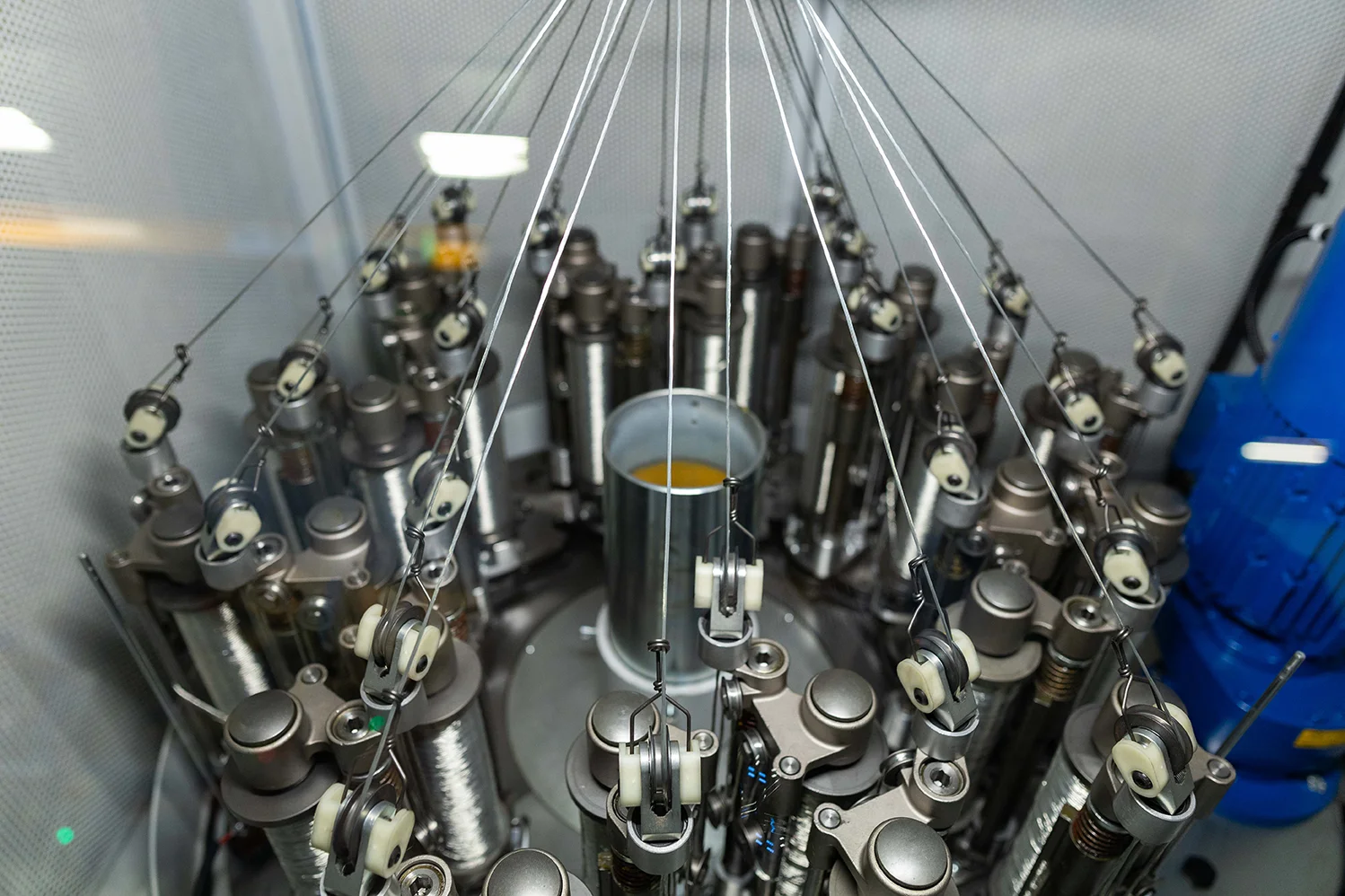

Conception and Design

Our flat braids are meticulously engineered using assemblies of single wires ranging from 0.1 mm to 0.2 mm in diameter. They are available in a flattened configuration and are made from high-purity copper with various coating options, including:

Bare copper

Tin-plated copper

The selection of braid type and wire diameter allows for optimal technical solutions tailored to the specific operating conditions. This careful optimization extends the service life of the braid, reducing maintenance and replacement costs.

Product Range

Standardized sections: Available from 2 mm² to 500 mm²

Wire diameter: Ranges from 0.1 mm to 0.2 mm

Finishes:

Bare copper

Tin-plated copper

The selection of braid type and wire diameter allows for optimal technical solutions tailored to the specific operating conditions. This careful optimization extends the service life of the braid, reducing maintenance and replacement costs.