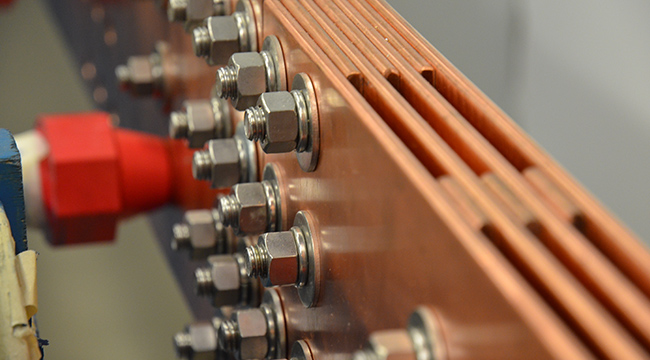

Copper and Aluminum Bus Bars

Bus bars are essential for conducting current in many settings. To benefit from optimal efficiency, ampacity, and life cycle in your bus bar, it’s critical to consider the quality of materials, design, and cross-sectional size.

Exel bus bars are manufactured with exclusive equipment employing cutting-edge technology we have designed. Consult with our experts for the best bus bar to meet your needs.

Materials used

Materials known for their conductivity properties are ETP C11000 copper and aluminum alloys 1350 and 6061. Other alloys can be used upon request.

Plating options

Electrolytic tin plating as per ASTM B545

Electrolytic silver plating as per ASTM B700

Electroless nickel plating as per ASTM B733

DIMENSIONS

Width up to 12”

Thickness up to 3”

Length up to 144”

Mounting holes as per NEMA standards

Custom sizes are also available.

CURRENT CAPACITY

Current capacity is determined by assembly configuration and bus dimensions. In some cases, current capacity can exceed 50,000 amperes.

OPTIONS

- Insulation: Heat shrink PVC and polyolefin, ceramic heat shield, powder coating and other types of insulation are available.

- Molded insulators for bus bars